POLYESTER FILM

Polyester Film

The fundamental raw material of polyester film is the polyethylene terephthalate in granule form. This material is combined with other added substances during the extrusion process, depending on the properties of the polyester film.

BoPET (biaxially-oriented polyethylene terephthalate)

The polyester films which are stretched in 2 axis during the production process, in order to direct the polymer chains into two directions, are called BoPET (biaxially oriented polyethylene terephthalate). Due to this complex manufacturing process, polyester films with high-tensile strengths can be produced.

Process

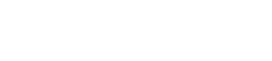

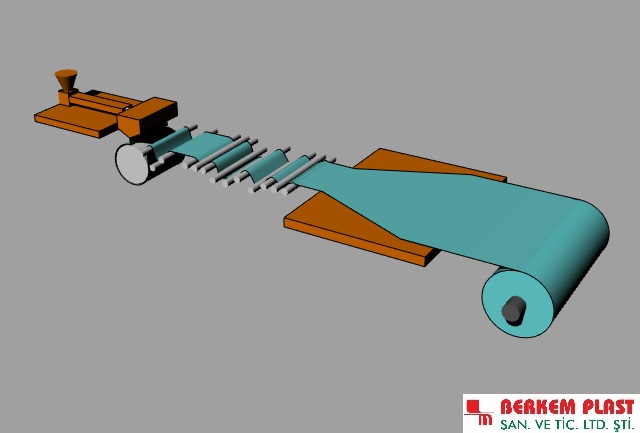

At the first stage of the production process, the liquified polyethylene terephthalate (PET) granules are poured on the controlled-heated roller, through the extrudes. During this stage, depending on the properties of the polyester film, additional catalyzers can be added, from the other two extrudes. Hence, the required properties on either surfaces are provided, without affecting the core. This process is called “co-ex production” and some of the polyester films produced by this method include: UV-resistant polyester films, mat-surfaced polyester films, heat activated adhesive polyester films. The amarphous, liquified polyester film goes through the rollers, which reduce their temperatures in a controlled manner, and starts its journey in the production line.

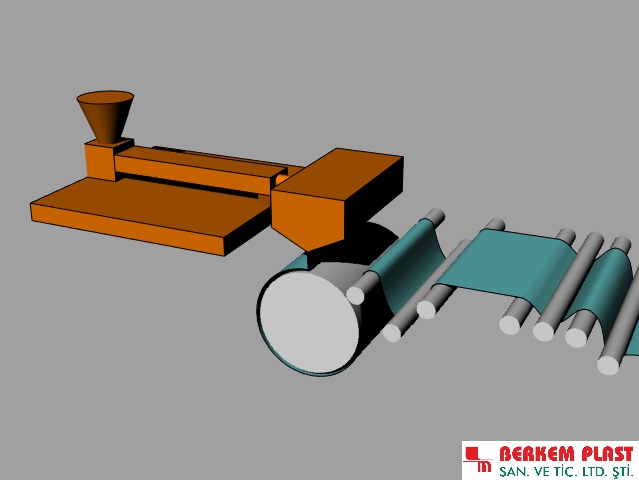

At the first stage, the temperature-controlled semi-liquid polyester film is stretched in the direction of the machine. This is called “machine direction orientation”. This stretching process is conducted by rotating the temperature -controlled roller mills at different rpm’s. Additionally, with the sensitive sensors, any defects on the polyester film can be detected.

The polyester film stretched by machine direction orientation is then stretched from the other direction, by fastening pliers on either sides of the polyester film. These pliers are also positioned on moving bands, next to the polyester films and they travel at the same speed. This process, where the polyester film is stretched in the direction prependicular to the machine direction is called “transverse direction orientation”.

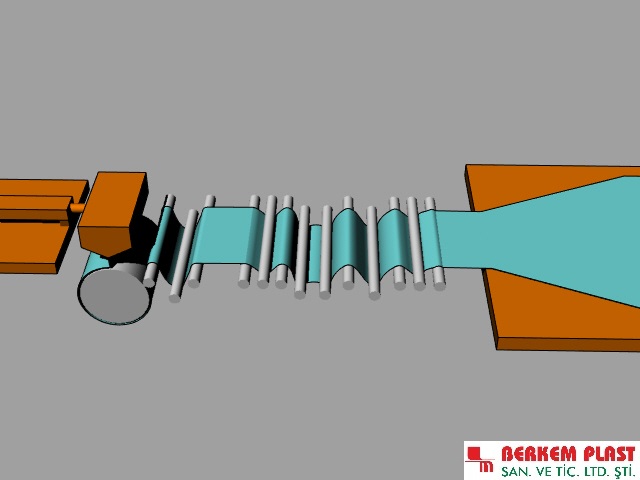

After being stretched in both directions, the polester film becomes “biaxially oriented”. This means, the polyester film’s polymer chains are directed in 2 axis. This makes the polyester film stronger and more durable than the other films, with an elasticity module of up tp 4 GPa.

After this process, the polyester film at above 200°C is cooled in a controlled way, in order to avoid the occurance of wrinkles, which breaks the polmer chains. Hence, the durability and transparency of the polyester film is ensured.

After the polyester film is wrapped around the jumbo-size roller mills, it becomes ready for the cutting process, based on the specifications provided by our clients.

This text was written by Bora Berkem and it is illegal to use it without a permission.

OTHER PRODUCTS